supercross-online.de

supercross-online.de

The Motion Control is a rather simple compression valve. The compression ports are covered by a variable port plate, controlling the LSC (Low Speed Compression) Using simple ports to control the oil flow results in an exponentially rise of the damping force. Little LSC paired with stiff HSC (High Speed Compression).

So the MC has no HSC? Well it has, kind of... When you have the compression adjuster fully closed, that essentially means the compression oil ports are closed, so no oil can flow and the fork cannot move. Well, in the real world, the fork should still move slightly to allow it to track well. The plastic compression tubes will compress slightly even when the fork is locked, allowing several millimeters of travel. When you hit something really big while locked out, the tube will compress enough for the poker to, literally, poke the compression valve cover out. This fully opens the oil flow for one hit, allowing the fork to soak up the hit, then a spring pushes it closed again.

Nevertheless, it doesn't work like a real HSC with shims or a blow off valve.

Another difference to the Lyric Charger is the open bath design of the MC. The oil covers the compression valve, but above the oil level there is no piston or bladder to seperate the oil from the air.

Coming from several Years of MX, a Yari is super plush compared to a MX fork. So it was a "just ride it" fork for me. I knew the day will come, when I am at least interested in how it works and maybe will see, what I can do to upgrade the Yari. Of course you can buy aftermarket valves but I rarely buy suspension parts 😎

But what can we do with the existing valve? The goal is to achieve less HSC for plusher fork action over roots and more LSC to stay higher in the stroke. So lets start...

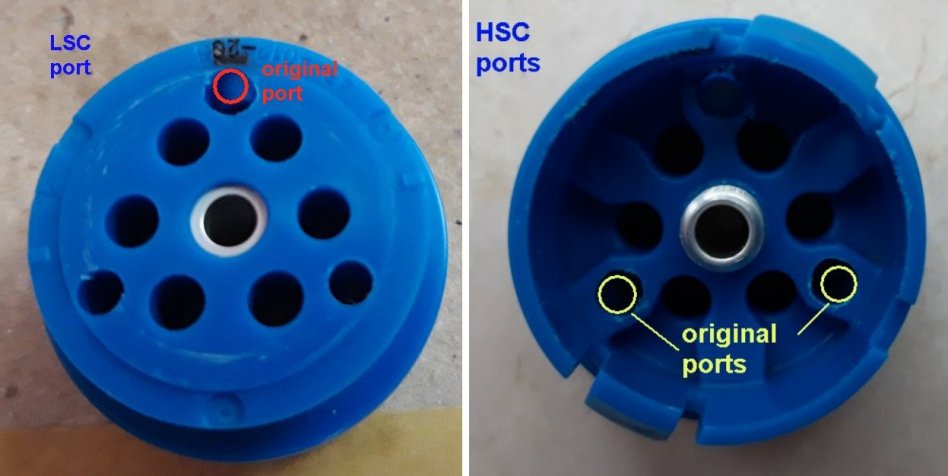

The MC I have (2017 Yari) has 3 ∅ 2.3mm ports , which results in 13mm2 cross sectional area at fully open compression. I decided to use one port for LSC and two ports for HSC. All 3 ports are bored to 3.5mm, that is 28.8mm2 overall. But they are not simply drilled out to 3.5mm because then the port plate could not fully cover the LSC port and the 22mm shims could not fully cover the HSC ports. I have increased the diameter of the ports a bit off-center, no big problem with a drill a bit forced to the right direction and a file. The LSC port alone now has 9.6mm2, I guess that's enough.

shimstack:

I have several shims laying around, so I have selected what was available

new shape of the port plate:

I didn't know if it's a good idea to to charge the shim stack off-center (only 2 of 3 ports) - especially because it's a plastic piston - but two years later it still works fine As expected, the surface is not 100% even, so my thougts about to use a ring shim are confirmed.

A weak point could be the restricted area between the 22mm face shim and the 24mm inner diameter of the compression valve unit. The ring shim needs to be centered, so some more of the area is restricted due to the noses of the ring shim. Nevertheless I will try it and see, if the highspeed hits will be reduced and also, if the oil flow in the other direction (refill at rebound) is high enough.